-

Call: +91 9324222495

-

Email: enquiry@qwpindia.com | sales@qwpindia.com

Our Products

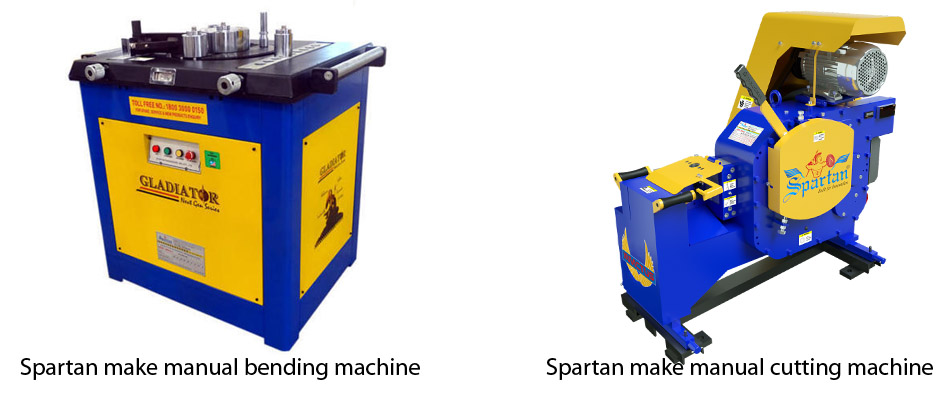

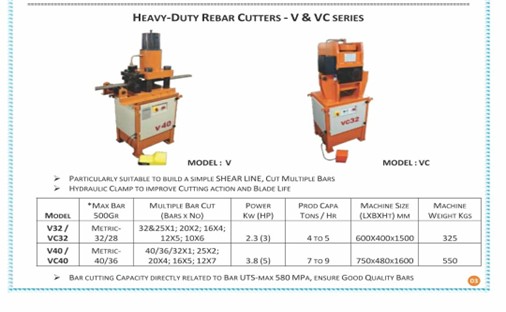

Rebar Processing with Cutting & Bending of Bars

Quality Wire Products engaged in Rebar Processing with Cutting & Bending of Bars in various applications in High Speed Rail & high rise buildings.

We use Automatic Shear Line, double Bender and Stirrup bender Machines. We can control wastage of straight bars up to 1.5% by using Software for cutting as per B.B.S.

Our production capacity is 4000 to 6000 Metric Tonnes per Month.

- REBAR PROCESSING MACHINERY

- SHEAR LINE

- Various Shapes & Sizes of Cut & Bend.

FANCING MESH ( WELD MESH);-WELDED WIRE MESH FENCE) AND ANTI - CLIMB FENCING:

- Fancing mesh

WELDED WIRE MESH is a steel fence conisting of wire strands electrically weld together to form a high strenth mesh. Welded together by parallel horizontal wire and vertical wire to form a storng panel. With proper size of the triangle bends and suitable colors of powder coating with variety of colour choices. Such as Yello,Green, & Red. It makes this product have a unique aesthetic effect with different colour combination of posts and mesh. Panels it makes the fencing very eye - pleasing.

- ANTI- CLIMB FENCING:

A unique perimeter security product that maintain a guarded display of visual screening balancing the need to delay and deter an attack. Anti- climb fencing combines a mesh that cutting and climbing with framework that can support a total security platform.

- USES OF FANCING MESH

Welded wire mesh fances are used predominantly as high security barriers where visibility thruogh the fance is necessary or desirable. It is also used in construction work, animal enclosures in ZOOS and private property.

- SECURITY:-

Atfer learn about the generat intoduction of our welded mesh fencing, you may trust its security easily. First of all, it welded by low carbon steel wire, it is absolutely much stronger than Wooden ones or bamboo ones; Second, the folds on the weld mesh panels can also increase its impact resistance against the out sise impact. Third, you can customized fence with the height and the size of the post you want, so to break a welded mesh fence, it may a quite hard job to do.

- APPLICATION SCENARIOS:-

Weld mesh fencing have a wide variety of using conditions. This kind of welded mesh can not only protect the private property like all fence do, but also decorate the place where it is used.Take the playground in school and Universities for example, Welded mesh fencing with with several folds and various colors will surely make the edge of theplayground more livly. Because the design is pretty gentle. Besides, welded fence panel aare more durable than the euro and chain fence, and the folds can also be changed into smaller ones and bigger ones accoring to the different requirements of the practical users.

- ECONOMIC:

Becaue of the processing and raw material, the welded mesh fencing price is quite economic amonge the big fencing system. The factors to influence the wire mesh fence prices are the wire thickness, the mesh size, the size, the post size. The thicker of the wire thickness, the smaller of the size, the bigger of the size, the price will be higher.

- THE INSTALLATION OF THE WELDED MESH FENCING:-

The installation of the welded mesh fencing is not so difficult. Generally speaking, there are mainly two waysto make them more stable standing on the ground. The first one is to use flange anchor bolts. Make sure the width of the fence panel and the distance between the two ports and measure the length between the two posts by there edges, and then make sure the length is the same.Then you can use the anchor bolts to fasten the flange tinghtly on the ground, and the ports will be stable at same. Next, usethe metal clamps or plastic clamp to make a connection with the panels.Calculation the length of the panels and make sure one clamp at least every 50cm vertically. The washier should be holding the wire and covered by clamps. The other way of installation is to bury the post into the earth. The length of the post under the ground can be changeable. But usually, 30cm-60cm are the most likely reasonable distance. So before sendind the posts into the ground, we need to dig holesfor installation. Firstly, measure the size of the posts. and make sure hole's diameter. Count the distance of the panels and make several centimeters more between the centres of the two holes. Use the spade to dig a hole and dig a hole parallel. Because we will make a little more room to send the post into the ground. Then send the post and make them stand vertically. Use the Anti UV-plastic clamps or metals clamps to connect the fence panel to the post. And make sure the length of the post standing on the ground stay the same with other posts.

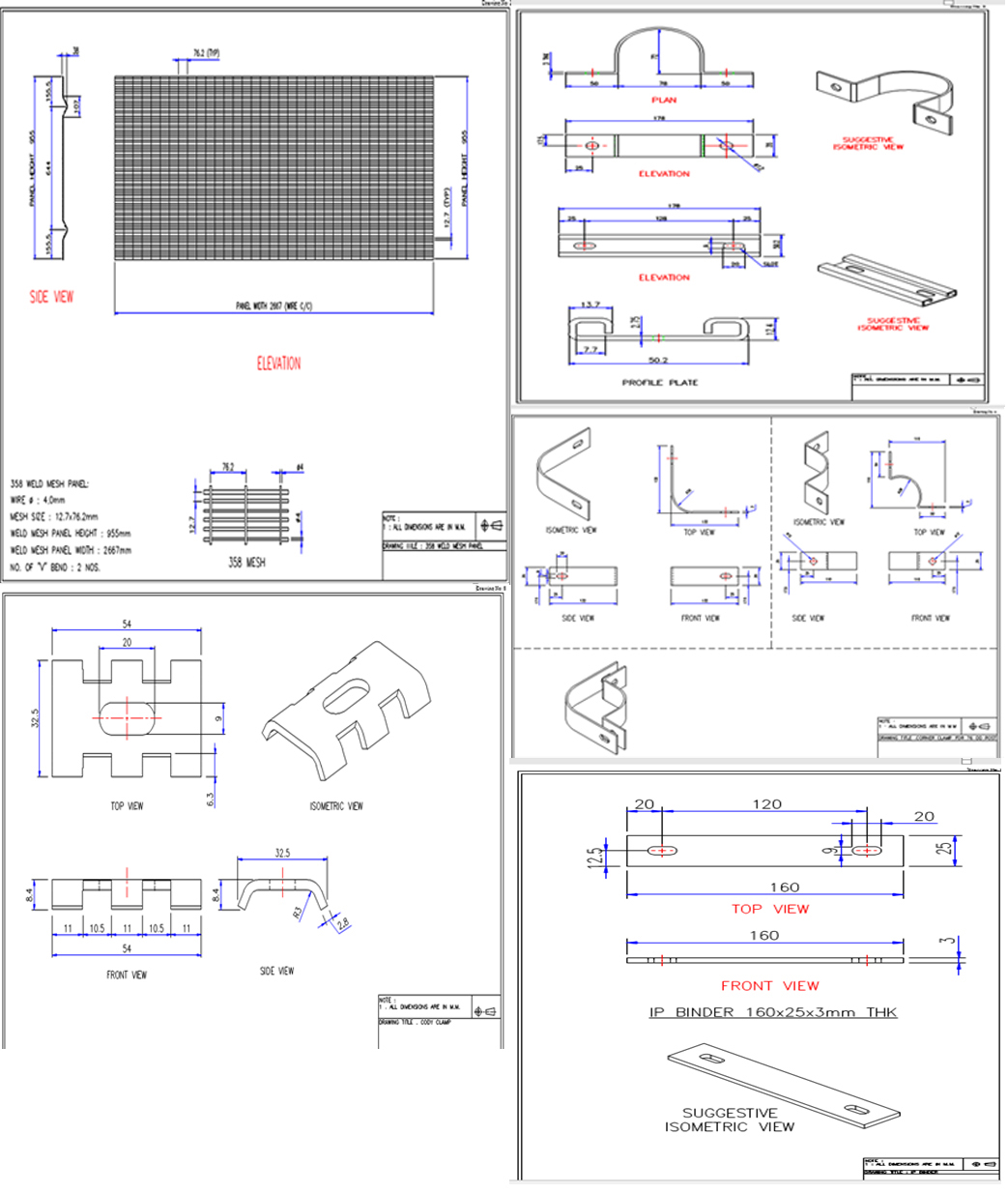

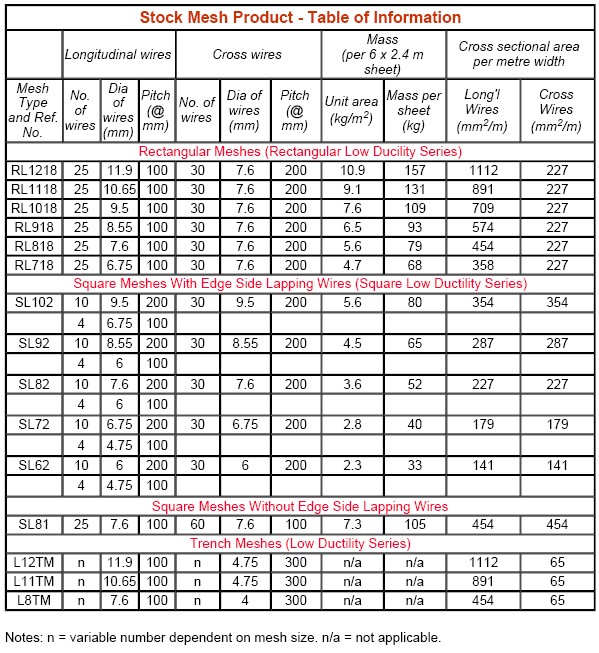

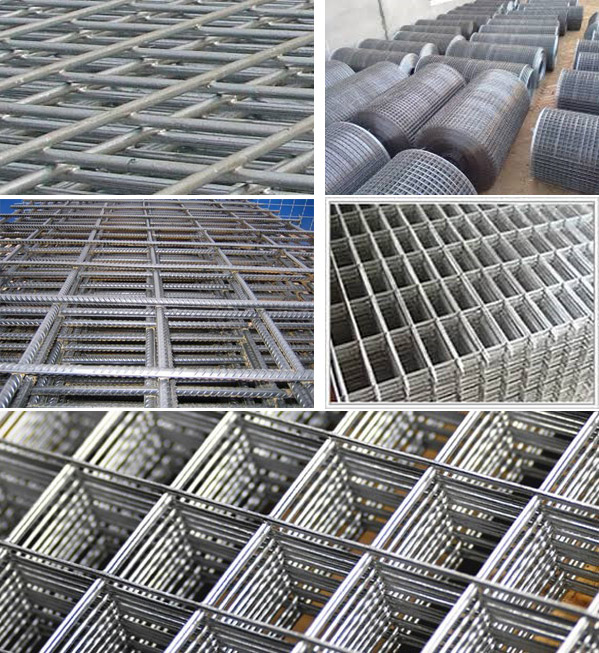

R.C.C. WELDED MESH

In construction Mild Steel bars are used to strengthen the cement concrete tensile strength and this procedure is known as Reinforced Cement Concrete (RCC). Welded mesh is a mesh made by welding wires at each intersection which are placed perpendicular to each other forming rectangular or square shapes. The advantages of using this welded wire fabric (WWF) in RCC are as follows:

- Is more stronger and durable since it is welded.

- Makes the procedure easier and faster as welding ensures not only in easier placing but also the bars don’t move and remain in place when cement concrete is poured on it to create the slabs.

- Reduces of labor requirement at site

- Reduces the wastage of construction materials

- Less placement of construction materials at site

- Maintain clean and safe environment

- Lessen the construction period and

- Lessen the cost as less steel is requires for reinforcement procedure.

Application of Welded Mesh in Construction Industries:

- Residential Buildings

- Soil Conditions

- Light Industrial Slab

- Supported Floor Slabs

- Concrete Shear Slabs

- Concrete Bridge Columns

- Precast Structures

- Pipe Reinforcement

Material used are

B.S.8110 with ultimate tensile strength of 570 N/mm2 and characteristic strength of 485 N/mm2

Manufacturing Range:

Wire Diameter: 2.00 mm to 16 mm

Mesh: 25 mm to 400 mm

Chain Link Fence

Chain-link fence is a type of woven fence, usually manufactured & fabricated by using Galvanized or coated Steel wire. The wires run vertically and bent into zigzag pattern. This forms the characteristics diamond pattern.

Material used are

- Hot Dipped Galvanized Wires

- PVC Coating.

Manufacturing Range:

- Wire Diameter: 1.6mm -4.00mm

- Roll Length: 1.0Mtr-50.00 Meter.

- Roll Width: 0.5 Mtr-5.00 Meters.

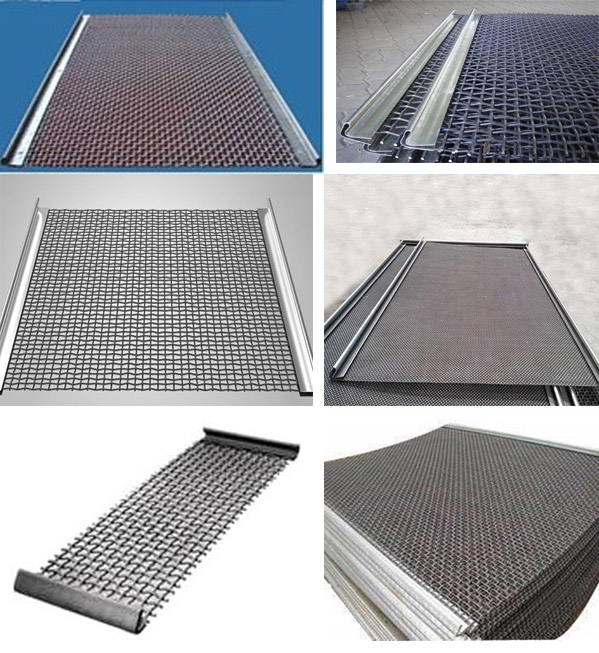

Crimped Wire Mesh

Crimped wire mesh or a square wire mesh is cloth made from wire strands which is pre-crimped thus making the warp and weft to remain relatively in correct position when it is woven. It is used in mining, coal factory, construction, cement industry, pharmaceuticals, petrochemical, minerals and chemical industries, rubber industries, automobile industries, food processing and many others.

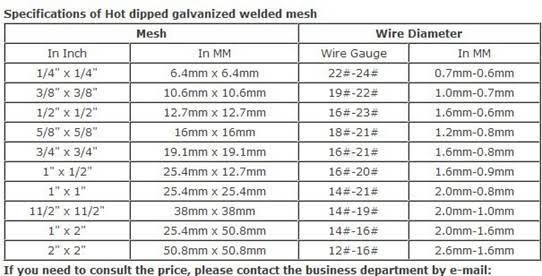

Welded Mesh and Welded Mesh Fence

Welded Mesh

Welded mesh is a mesh made by welding wires at each intersection which are placed perpendicular to each other forming rectangular or square shapes. Welded mesh are used in :

- Construction.

- Agricultural

- Industrial

- Mines

- Poultry and etc.

Material used are :

B.S.8110 with ultimate tensile strength of 570 N/mm2 and characteristic strength of 485 N/mm2

Manufacturing Range:

Wire Diameter: 2.00 mm to 12 mm

Mesh: 25 mm to 400 mm

Welded Mesh Fence

Welded wire mesh fence is design & fabricate not only for boundary protection but it also provide aesthetic appeal. It is used for fencing commercial and residential complexes, schools premises, parks gardens and etc. At Quality Wire Products we manufacture customized fences as per customer’s requirement.

Material used are :

Galvanized Wires, Mild Steel Wires or Stainless Steel Wires.

Manufacturing Range:

Wire-0.50mm -6.00mm

Section-10.0mm to 200mm

Welding Width ranges from 300mm to 2000mm.

Vibrating Screens

Vibrating screen manufactured in Mild steel, Galvanized iron or stainless steel material and used as filtration medium for sieving in a wide range of industries.